Not all chargers are created equal. It's time to learn if your portable charger is safe. Learn more about our 12 step safety check. It ensures each myCharge battery manufactured is safe for you, your family or friends to use. Rest assured.

Battery Selection Process

Before a battery is selected, the battery factory is audited to ensure best practices are followed for lithium batteries regarding manufacturing, quality control and research and design.

Battery Cycle Test

Once a factory passed the audit - several batteries our cycle tested for efficiency and charge retention.

UL Battery Testing

It is a myCharge internal guideline that each battery must meet UL testing requirements for durability.

Battery Charge Testing

Several different states of battery state of charge are simulated to ensure battery is being charged to proper algorithm as defined by battery manufacturer.

Smart Control Battery Safety Test

Over 12 layers of protection against over-charge, under-charge, over-temperature, short circuit and over-current. Failure modes are simulated for each protection level to ensure all systems are operating as expected.

Durability

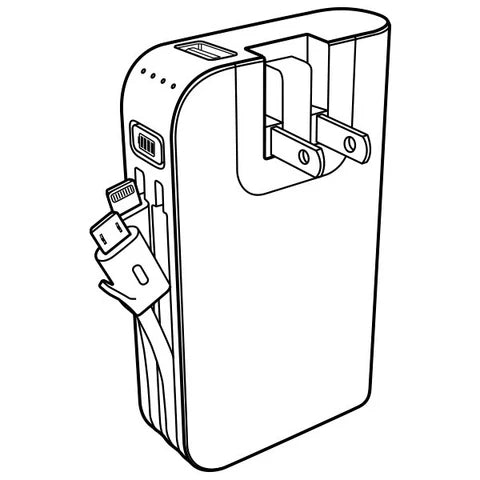

Product drop tested a total of 30 times from a height of 1m (5 times each side) to check to structural integrity. Connectors and cables are tested to several thousand insertion and bend cycles.

Accelerated Aging Test

Product tested in high temperature high humidity to simulate affects of harsh conditions and accelerated aging on product components to confirm robustness of end product.

Compatibility Testing

Actual charge testing completed with several different platforms. It takes an in depth understanding of how devices charge to understand how to design the perfect universal charging solution.

Input/Output Testing

Each product is tested to confirm inputs and outputs are working as expected.

Charge/Discharge Test

Each product is fully charged and fully discharged to simulate real use case and to ensure energy delivered to devices is as expected.

Visual Inspection

After subject to extreme testing such as durability and accelerated aging test, product is disabled and analyzed under microscope to inspect for signs of weakness in design.

Transportation Testing

Product is tested to ISTA transportation test requirements and subject to drop and vibration testing to ensure no safety issue. Product is tested to UN38.3 transportation testing to ensure no safety issue when transported on plane.